1-1/2″ Deep Impact Sockets

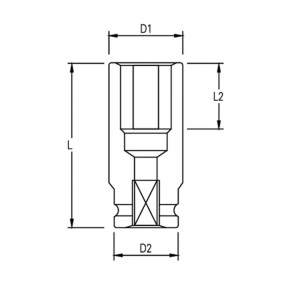

product parameters

| Code | Size | L | D1±0.2 | D2±0.2 |

| S163-30 | 30mm | 115mm | 52mm | 74mm |

| S163-32 | 32mm | 115mm | 54mm | 74mm |

| S163-34 | 34mm | 115mm | 55mm | 74mm |

| S163-36 | 36mm | 115mm | 58mm | 74mm |

| S163-38 | 38mm | 115mm | 60mm | 74mm |

| S163-41 | 41mm | 160mm | 64mm | 74mm |

| S163-42 | 42mm | 160mm | 65mm | 74mm |

| S163-45 | 45mm | 160mm | 68mm | 74mm |

| S163-46 | 46mm | 160mm | 70mm | 74mm |

| S163-50 | 50mm | 160mm | 74mm | 74mm |

| S163-52 | 52mm | 160mm | 76mm | 74mm |

| S163-54 | 54mm | 160mm | 78mm | 74mm |

| S163-55 | 55mm | 160mm | 79mm | 74mm |

| S163-56 | 56mm | 160mm | 82mm | 74mm |

| S163-58 | 58mm | 160mm | 87mm | 74mm |

| S163-60 | 60mm | 160mm | 90mm | 80mm |

| S163-65 | 65mm | 160mm | 98mm | 80mm |

| S163-70 | 70mm | 160mm | 102mm | 80mm |

| S163-75 | 75mm | 160mm | 107mm | 80mm |

| S163-80 | 80mm | 170mm | 114mm | 94mm |

| S163-85 | 85mm | 170mm | 119mm | 84mm |

| S163-90 | 90mm | 170mm | 128mm | 90mm |

| S163-95 | 95mm | 180mm | 13mm | 90mm |

| S163-100 | 100mm | 190mm | 136mm | 90mm |

| S163-105 | 105mm | 190mm | 139mm | 90mm |

| S163-110 | 110mm | 200mm | 144mm | 90mm |

| S163-115 | 115mm | 210mm | 154mm | 90mm |

| S163-120 | 120mm | 210mm | 159mm | 90mm |

| S163-125 | 125mm | 210mm | 164mm | 100mm |

| S163-130 | 130mm | 210mm | 169mm | 110mm |

introduce

1-1/2" Deep Impact Socket: The Ultimate High Torque Solution

A reliable set of tools is essential when it comes to tackling heavy-duty tasks that require high torque and precision. The 1-1/2" Deep Impact Socket is one such tool that stands out in the automotive and industrial fields. Engineered for superior strength and durability, this long socket is built to withstand the toughest tasks. In this In this blog post, we'll explore key features and benefits of these sockets, such as CrMo steel material, forged construction, corrosion resistance, and OEM support.

Durable: CrMo steel material

1-1/2" Deep Impact Sockets are constructed of CrMo (Chromium Molybdenum) steel material. This premium alloy is known for its superior strength and wear resistance. By using CrMo Steel, these sockets can handle high volume impacts Impact wrenches generate torque that ensures smooth and efficient operation every time.

details

Durable forged construction

Another standout feature of these deep impact sockets is their forged construction. Through heat and pressure, the socket is shaped and strengthened to handle the high forces encountered in heavy-duty applications. The forged design increases the life and reliability of the outlet, making it an investment that lasts for many years.

Anti-corrosion properties

Over time, exposure to moisture and the elements can cause tools to rust and deteriorate. However, with their anti-corrosion properties, these deep impact sockets are resistant to such damage. Whether you're working in challenging weather conditions or less-than-ideal environments, you can trust these sockets will maintain their performance and appearance, ensuring your tools will last and won't let you down.

Peace of mind with OEM support

To ensure the highest level of compatibility and quality, the manufacturer of these deep impact sockets offers OEM support. This means that these sockets are designed according to the specifications set by the original equipment manufacturer. OEM support guarantees precise fit, optimum performance, and compatibility with a wide range of equipment, giving you the peace of mind of a reliable tool you can trust.

in conclusion

In summary, if you need a socket that can handle high torque applications, the 1-1/2" deep impact socket is the ultimate solution. With its CrMo steel material, forged construction, corrosion resistance, and OEM support, it is designed to handle even the toughest Tough job.Invest in these sockets and experience the power and performance that only a quality tool can provide.