1″ Impact Sockets

product parameters

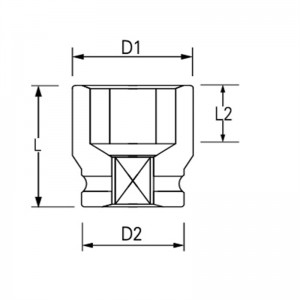

| Code | Size | L | D1±0.2 | D2±0.2 |

| S157-17 | 17mm | 60mm | 34 | 50 |

| S157-18 | 18mm | 60mm | 35 | 50 |

| S157-19 | 19mm | 60mm | 36 | 50 |

| S157-20 | 20mm | 60mm | 37 | 50 |

| S157-21 | 21mm | 60mm | 38 | 50 |

| S157-22 | 22mm | 60mm | 39 | 50 |

| S157-23 | 23mm | 60mm | 40 | 50 |

| S157-24 | 24mm | 60mm | 40 | 50 |

| S157-25 | 25mm | 60mm | 41 | 50 |

| S157-26 | 26mm | 60mm | 42.5 | 50 |

| S157-27 | 27mm | 60mm | 44 | 50 |

| S157-28 | 28mm | 60mm | 46 | 50 |

| S157-29 | 29mm | 60mm | 48 | 50 |

| S157-30 | 30mm | 60mm | 50 | 54 |

| S157-31 | 31mm | 65mm | 51 | 54 |

| S157-32 | 32mm | 65mm | 52 | 54 |

| S157-33 | 33mm | 65mm | 53 | 54 |

| S157-34 | 34mm | 65mm | 54 | 54 |

| S157-35 | 35mm | 65mm | 55 | 54 |

| S157-36 | 36mm | 65mm | 57 | 54 |

| S157-37 | 37mm | 65mm | 58 | 54 |

| S157-38 | 38mm | 70mm | 59 | 54 |

| S157-41 | 41mm | 70mm | 61 | 56 |

| S157-42 | 42mm | 70mm | 63 | 56 |

| S157-46 | 46mm | 70mm | 68 | 56 |

| S157-48 | 48mm | 70mm | 70 | 56 |

| S157-50 | 50mm | 80mm | 72 | 56 |

| S157-55 | 55mm | 80mm | 78 | 56 |

| S157-60 | 60mm | 80mm | 84 | 56 |

introduce

Impact sockets are an essential tool for any mechanic. Whether you're a professional mechanic or a weekend DIYer, having a set of high-quality impact sockets can make your job easier and more efficient. When it comes to impact sockets, there are a few key features to consider: high torque capacity, durable construction, and a variety of sizes.

An important characteristic to consider when selecting an impact socket is the material it is made of. CrMo steel is a steel known for its strength and durability, making it an excellent choice for impact sockets. The forged construction of these sockets further enhances their strength and ensures that they can withstand high torque levels without cracking or breaking.

Another important factor to consider is the number of points on the socket. Impact sockets typically come in a 6-point or 12-point design. The 6-point design is preferred by many mechanics because it provides a firmer grip on fasteners, reducing the risk of slipping and rounding.

In terms of size range, a good set of impact sockets should cover a variety of sizes to accommodate different fasteners. From 17mm to 60mm, a comprehensive set of sockets ensures you have the right size socket for any job you come across.

details

Industrial grade impact sockets undergo rigorous testing to ensure durability and reliability. These sockets are built to withstand frequent use in harsh environments without wear and tear. They are designed to deliver consistent performance even in the harshest conditions, making them the trusted choice for professionals.

An important consideration when it comes to impact sockets is their rust resistance. The last thing you want is an outlet that's rusted and hard to use. Look for impact sockets that are specifically designed to resist rust, ensuring they will last for years.

Finally, it's worth mentioning that OEM support is critical in delivering high quality, compatible impact sockets. With OEM Support, you can rest assured that you are getting an authentic, reliable product backed by the original manufacturer.

in conclusion

In conclusion, impact sockets play a vital role in any mechanic's toolbox. Factor in features such as high torque capacity, CrMo steel material, forged construction, 6-point design, size range, industrial grade quality, rust resistance and OEM support to ensure you invest in an impact socket that will meet your needs. Needed and withstood the test of time. So, whether you're a professional or a DIYer, be sure to choose an impact socket that's durable and delivers the performance you need.