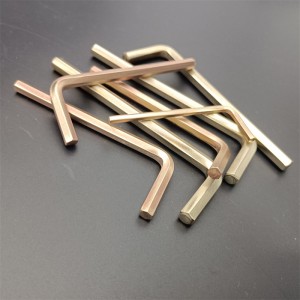

1143A Wrench, Hex Key

Non-Sparking Single Box Offset Wrench

|

Code |

Size |

L |

H |

Weight |

||

|

Be-Cu |

Al-Br |

Be-Cu |

Al-Br |

|||

|

SHB1143A-02 |

SHY1143A-02 |

2mm |

50mm |

16mm |

3g |

2g |

|

SHB1143A-03 |

SHY1143A-03 |

3mm |

63mm |

20mm |

5g |

4g |

|

SHB1143A-04 |

SHY1143A-04 |

4mm |

70mm |

25mm |

12g |

11g |

|

SHB1143A-05 |

SHY1143A-05 |

5mm |

80mm |

28mm |

22g |

20g |

|

SHB1143A-06 |

SHY1143A-06 |

6mm |

90mm |

32mm |

30g |

27g |

|

SHB1143A-07 |

SHY1143A-07 |

7mm |

95mm |

34mm |

50g |

45g |

|

SHB1143A-08 |

SHY1143A-08 |

8mm |

100mm |

36mm |

56g |

50g |

|

SHB1143A-09 |

SHY1143A-09 |

9mm |

106mm |

38mm |

85g |

77g |

|

SHB1143A-10 |

SHY1143A-10 |

10mm |

112mm |

40mm |

100g |

90g |

|

SHB1143A-11 |

SHY1143A-11 |

11mm |

118mm |

42mm |

140g |

126g |

|

SHB1143A-12 |

SHY1143A-12 |

12mm |

125mm |

45mm |

162g |

145g |

introduce

Sparkless Hex Wrench: Enhanced Safety in Hazardous Environments

Safety is paramount in hazardous environments where flammable gases, vapors or dust particles are present. Industries such as oil and gas require specialized tools that provide maximum safety without compromising efficiency. Spark-free hex wrenches, also known as spark-free hex wrenches, provide the perfect solution. These industrial-grade safety tools have the unique qualities of being non-magnetic, corrosion-resistant, and high-strength, making them ideal for use in hazardous environments.

Explosion-proof hexagonal wrench - ensure safety:

The main advantage of a sparkless hex wrench is its ability to eliminate sparks, reducing the risk of igniting flammable materials. Designed for use in spark-sensitive environments, these tools are made from non-sparking alloys such as copper beryllium (CuBe) or aluminum bronze (AlBr) to prevent any potential ignition sources.

Non-magnetic and corrosion-resistant:

In addition to their non-sparking properties, their non-magnetic properties make these hex wrenches ideal for working in environments where magnetic fields need to be avoided. Their corrosion-resistant properties provide additional durability even when exposed to harsh chemicals or corrosive elements common in the oil and gas industry.

details

Unyielding strength and industrial-grade design:

Spark-free hex wrenches are designed to withstand heavy-duty applications. Its high-strength composition ensures durability and reliability even under extreme conditions. By providing optimal torque and precise assembly, these tools help complete the job efficiently, making them a valuable asset in industrial settings.

Ideal for the oil and gas industry:

The oil and gas industry requires strict safety measures due to the high risk associated with flammable substances. Therefore, using a spark-free hex wrench is critical to minimizing potential hazards. These security tools are designed to work flawlessly in an environment where security protocols are strictly enforced. With their reliable performance, they significantly reduce the risk of accidents and ensure worker safety.

in conclusion

When it comes to hazardous environments, safety should never be sacrificed. Non-sparking hex wrenches offer reliable solutions with the unique qualities of non-sparking, non-magnetic, corrosion-resistant, high-strength and industrial-grade design. These safety tools provide peace of mind to industries like oil and gas, where keeping workers safe is critical. Investing in a spark-free hex wrench is a proactive measure that promotes a safe work environment and supports efficient operations in hazardous environments.