Impact Universal Joints

product parameters

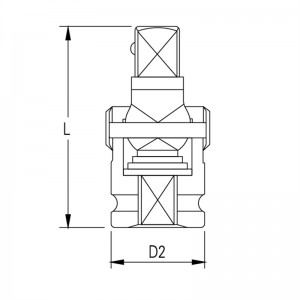

| Code | Size | L | D |

| S170-06 | 1/2" | 69mm | 27mm |

| S170-08 | 3/4" | 95mm | 38mm |

| S170-10 | 1" | 122mm | 51mm |

introduce

Universal joints are integral components in a variety of mechanical systems, ensuring the smooth transfer of torque and motion between misaligned shafts. When high torque applications are involved, impact universal joints are the first choice. Manufactured from high-quality materials such as chrome-molybdenum steel, these strong and efficient components are able to withstand intense stress and provide reliable performance.

details

Sometimes it can be challenging to find a gimbal that fits perfectly with different shaft sizes. However, with the Shock Gimbal, this is no longer an issue. They are available in three different sizes: 1/2", 3/4" and 1". This wide range ensures compatibility with various shaft sizes, providing flexibility and convenience during assembly and maintenance sex.

One of the key factors that give Impact gimbals a competitive edge is their superior build quality. These joints are made of forged chrome molybdenum steel for added strength and durability. The forging process ensures that these components can withstand the heavy loads, high-speed rotation, and harsh working environments often associated with heavy machinery. With an impact gimbal, you can rest assured that your equipment is equipped with reliable and durable parts.

Additionally, impact gimbals are OEM supported, which means they can seamlessly replace OEM parts. This not only simplifies the procurement process, but also guarantees compatibility and performance. By choosing an impact gimbal as a replacement, you can ensure your equipment maintains its efficiency and reliability without compromising quality.

in conclusion

In conclusion, impact universal joints provide an excellent solution for high torque applications. They are available in 1/2", 3/4" and 1" sizes to accommodate a variety of shaft sizes. The use of chrome molybdenum steel material forged during the manufacturing process ensures strength and durability and holds up to heavy loads capabilities. Plus, their OEM support makes them an easy choice for equipment maintenance and replacement. Choose impact gimbals for your mechanical system and experience the difference in the performance and reliability they offer.